Pile Tests Reports

| Document Name | GEO TECHNICAL ASSESSMENT REPORT |

| Document Number | SK-2020-TETHYS-RAMAGUNDAM-01 |

| Revision | R6 |

| Submission Date | 21/07/2020 |

| Project Name | Geo technical Assessment Report for Construction of Floating Solar Power Plant Ramagundam |

| Revision | Date | Changes/ Comments | |

| R0 | 19/06/20 | Draft Submission | |

| R1 | 25/06/20 | Lateral Capacity by Broms Method included | |

| R2 | 03/07/20 | Comment incorporated & Supporting document attached | |

| R3 | 07/07/20 | 15mm Lateral deflection incorporated | |

| R4 | 11/07/20 | Comment incorporated (f=25) | |

| R5 | 18/07/20 | Comment incorporated | |

| R6 | 21/07/20 | Lateral & uplift Capacity Calculation updated |

GEOTECHNICAL ASSESSMENT REPORT FOR PROPOSED FLOATING SOLAR POWER PLANT RAMAGUNDAM

1. Introduction/Executive Summary

Bharat Heavy Electricals Limited (BHEL) has issued work order for the construction 100 MW AC floating solar project for the National Thermal Power Corporation (NTPC)at the Ramagundam, Peddapeli District, Telangana. Floating solar panel /structures are subject to the influence of wind, current and wave, exerting on each float of the structure of the forces that will be transmitted via the links to the other floats of the structure, and to the points of anchorage. To anchor a floating structure/ panel by means of anchoring systems below the floating structure.

As a statutory requirement & to identify required design parameters for safe design ,M/s Tethys Business and Projects(P)Ltd. decided to carry out geo technical assessment for the proposed anchor age system. Geo technical assessment work consisted of estimation of geotechnical Lateral & uplift capacity of the anchorage system by reviewing the available Geotechnical Information & drawing.

The purpose of the study is to estimate the Lateral & uplift capacity of the anchorage system from the geotechnical point of view.

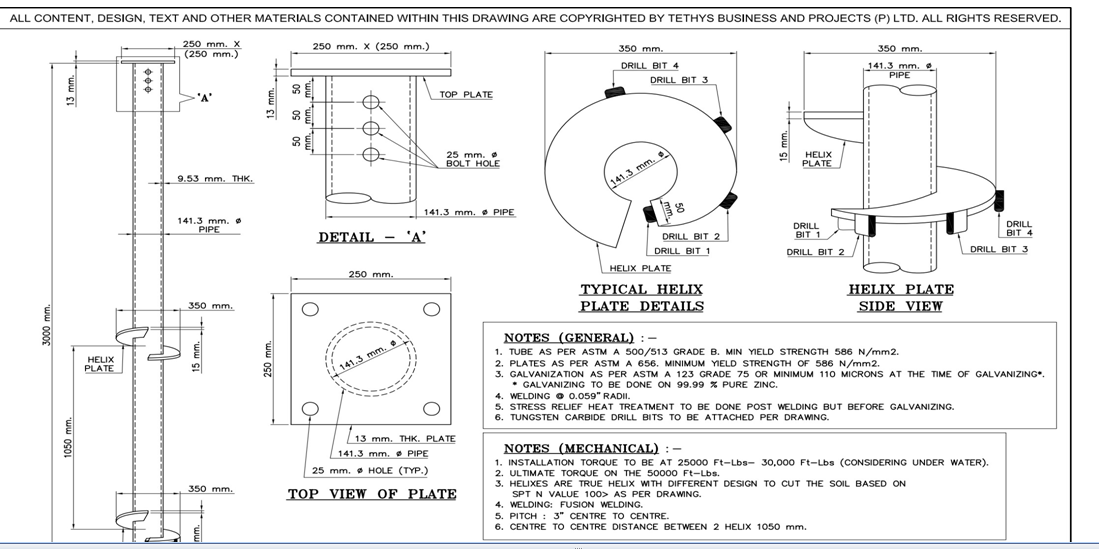

- The approximate floating Solar panel 174m X 190m in size will anchorage by 40 or more anchor system.

- Centre to center between anchorage system will be 5m

- Length of the anchorage system will be 3m minimum

- Diameter of the anchorage system will be 350 mm

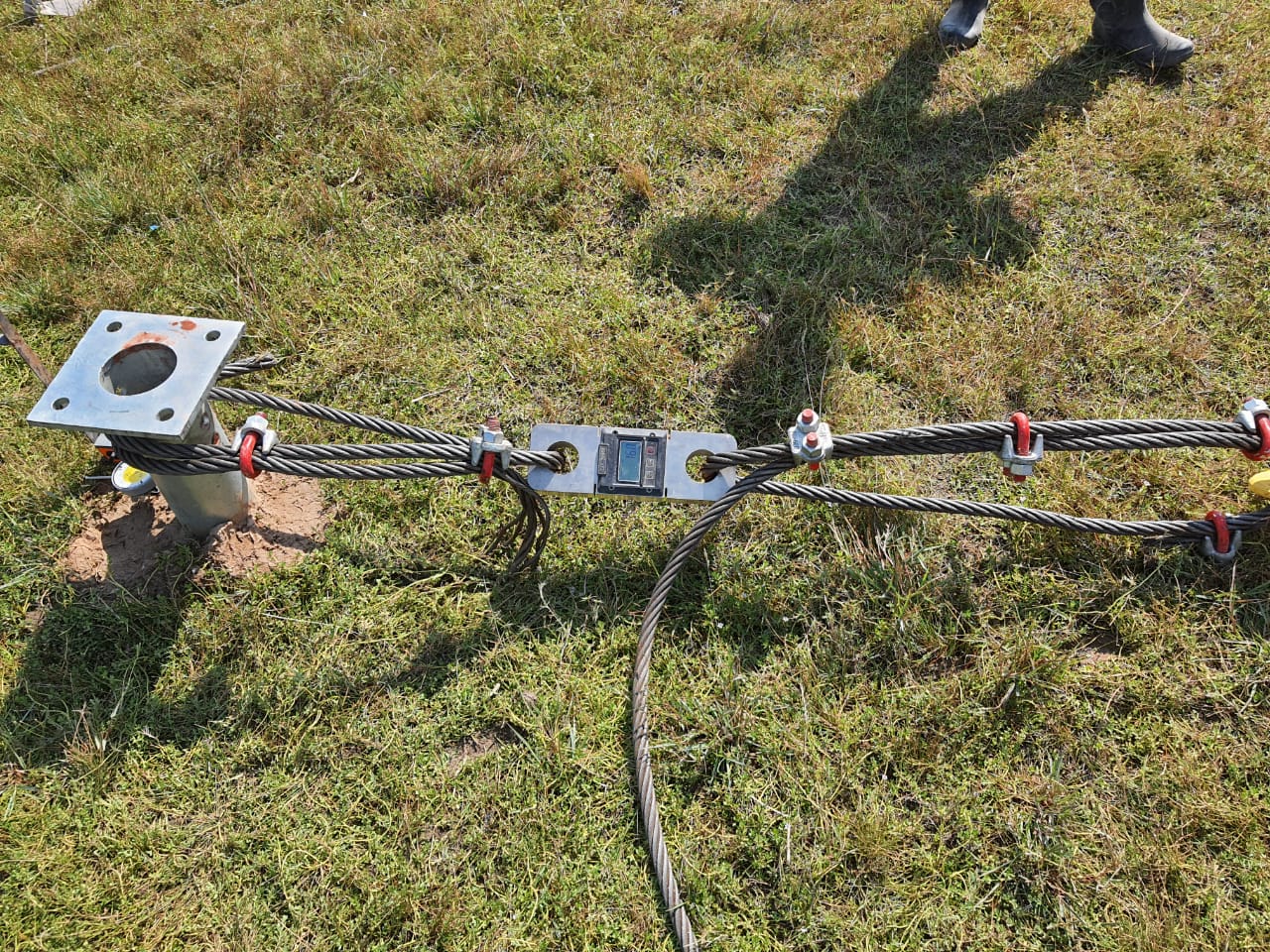

Figure1TypicalImageFloatingSolarPanels

It was conveyed to the geo technical Consultant that total anticipated load of 2.0T lateral & 1.17T uplift will be acting on the anchorage system as per the structural/mooring analysis. After studying the available Geo technical information, it was observed that completely weathered rock was present below the reservoir bed where anchor age system will be installed to hold the floating panels. Lateral & uplift capacity of the anchorage system was established by using available literature i.e. International literature & IS codes. The estimated capacity is as per follow

Table1

Estimated capacity for Anchorage System

Shaft Dia in mm |

Type of Capacity | Founding Depth bed level in m |

Foundation Strata | Geo technical Capacity (T) |

141.3 | Uplift Capacity | 3.00 | Completely Weathered Rock | 1.510 |

Lateral Capacity by Broms Method | 3.00 | Completely Weathered Rock | 2.00 |

2. Geotechnical Findings

Total five underwater bore holes were drilled for the proposed work, where water depth varies from 2 to 5m. The field work is summarized in below table –

Table2

Summary of Bore hole Logs

Sr. No. |

BH No. |

BH Location |

RL | SOIL or Soft Rock Thickness (m) | ROCK Thickness (m) | TOTAL Drilled Depth (m) |

1 | BH01 | E=336746.00 N=2072625.00 | 165.125 | 3.00 | 2.00 | 5.00 |

2 | BH02 | E=337297.00 N=2072514.00 | 160.137 | 3.00 | 2.00 | 5.00 |

3 |

BH03 | E= 337550.00 N=2072115.00 |

161.737 |

4.00 |

1.00 |

5.00 |

4 | BH04 | E=338454.00 N=2071854.00 |

157.758 |

2.00 |

3.00 |

5.00 |

5 | BH05 | E=337775.00 N=2071226.00 | 161.396 | 3.00 | 2.00 | 5.00 |

- Stratification:

Based on the five-borehole drilled and field and laboratory tests on selected samples the following soil stratification can be revealed at this location. Following sub soil Layers profile was inferred up to final depth of borehole.

Table3

Description of Layers at proposed structure

Layer Number | Description | Grade of Strata | Average Thickness (m) within Project area |

Layer 1 | Dense to very Dense Sand (Completely Weathered Sandstone) | V | 2.00 to 4.00 |

Layer 2 | Highly Weathered Sandstone | IV | 1.00 to 2.00 |

Layer–1 Dense to Very Dense SAND (Completely Weathered Sandstone)

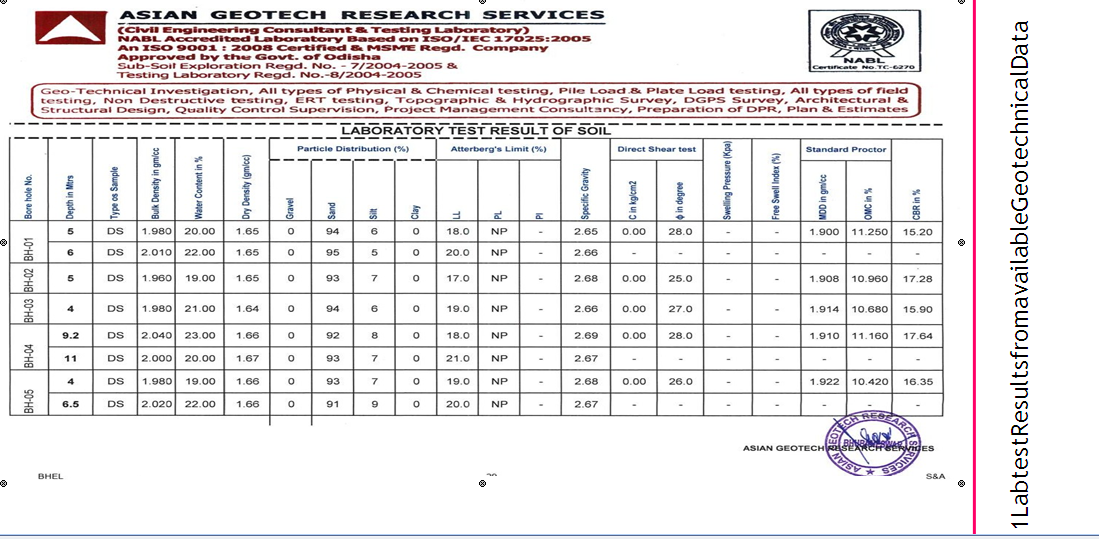

First stratum of sub soil profile is Dense to very dense SAND i.e. Completely Weathered Sandstone. This layer consists of clay and silt in varying percentage of sand. This layer has an average thickness of 2.00 to 4.00 m in the project area. Standard penetration tests were conducted in this stratum to check consistency of the stratum. Reported ‘N’ values are REFUSAL shows dense to dense consistency. Examination of sample collected that it was completely weathered sand stone rock having brownish stiff to stiff clay mixed with gravels and boulders/ residual rock structure, which is locally known as Soft murrum. Grain sieve analysis was conducted on the disturbed samples, result shows that silty sand – well graded sand mixed with silt i.e. SM-SC. Maximum Liquid limit varies from 17 to 21 % and Plastic Limit is Non Plastic. Grain Sieve analysis & Atterberg tests were conducted on the selected samples, following are the range for the various tests

Table4 Layer I Denses and (Completely Weathered Sandstone) Lab Result (Soil)

Sr No | Description of Test | Unit | Test Results |

1 | IS Soil Classification | — | SM-SC |

2 | Gravel | % | 0 |

3 | Sand | % | 91to95 |

4 | Silt | % | 5 to9 |

5 | Clay | % | 0 |

6 | Liquid limit | % | 17to21 |

7 | Plastic Limit | % | Non-Plastic |

8 | Plasticity Index | % | Non-Plastic |

9 | Specific Gravity | — | 2.65to2.68 |

10 | Bulk Density | gm/cc | 1.960to2.020 |

Layer–2 Highly weathered Sandstone Rock

Second stratum of subsoil profile is Highly weathered rock. This stratum is present in all boreholes & boreholes were terminated in this stratum. Average thickness of this stratum is varying between 1.00 m to 2.00 m in boreholes. Examination of sample collected that it was highly weathered rock mixed with gravels and boulders/residual rock structure, which is locally known as Hard murrum. Due to the presence of boulders in this stratum; core recovery & RQD value were recorded. Rock core recovery value recorded from Nil to 18%, these values of rock recovery show completely to highly weathered condition of rock stratum. Rock quality designation values are recorded NIL in drill runs. These indicate poor state of rock mass.

3. Code & Standards

The assessment was carried out as per relevant important Indian Standards and codes of Indian Road Congress. The following codes shall be followed for the project:

Table 5 Reference Codes & Documents

CIRIA 180 | : | Pile Foundation in Weak Rock |

CIRIA 580 | : | Embedded Retaining Wall |

BS 8081:2015 | : | Ground Anchor |

Journal of Geo technical Engineering | : | Pull out Capacity of Screw Piles in Sandy Soil (ISSN:2394-1987 (Online) Volume4, Issue1 |

Ottawa Geo 2007 | : | Kristen MT, David CS. Predicting the Axial Capacity of Screw Piles Installed in Canadian Soils. |

Geo technique. 1993; 43:605 – 614 | : | Narasimha Rao S, Prasad YVSN, Veeresh C. Behaviors of Embedded Model Screw Anchors in Soft Clays. |

Research Paper North western University US | : | Pull out Load Capacity of a Circular Earth Anchor Buried in Sand (WALLACE H. BAKER and ROBERTL.KONDNER) |

ASCE, No.SM2, pp.27-63 | : | Broms, B.B.(1964a), Lateral Resistance of Piles in Cohesive Soils, Journal of SMFED, Proc. |

ASCE,No.SM3, pp.123-156 | : | Broms, B.B.(1964b), Lateral Resistance of Piles in Cohesion less Soils, Journal of SMFED, Proc. |

Geo-Chicago2016GSP270 | : | Lateral Performance of Helical Piles as Foundations for Offshore Wind Farms: Sherif A.Y.Akl; Omar M. Elhami; and Mustafa A.Abu-keifa |

EJGE; Vol. 17 [2012], Bund. R | : | Performance of Helical Anchors in Sand;(Hamed Niroumand, Khairul Anuar Kassim, Amin Ghafooripour, Ramli Nazir1, H.S. Chuan) |

The Japanese Geotechnical | : | Soils and Foundations; Analysis and design methods of screw piles: Are view; Abbas Mohajeranin, Dusan Bosnjak, Damon |

CIRIA180 | : | Pile Foundation in Weak Rock |

CIRIA580 | : | Embedded Retaining Wall |

BS8081:2015 | : | Ground Anchor |

Journal of Geotechnical Engineering | : | Pull out Capacity of Screw Piles in Sandy Soil(ISSN:2394-1987(Online) Volume4,Issue1 |

Ottawa Geo 2007 | : | Kristen MT, David CS. Predicting the Axial Capacity of Screw Piles Installed in Canadian Soils. |

Geotechnique.1993;43:605– 614 | : | Narasimha Rao S, Prasad YVSN, Veeresh C. Behaviors of Embedded Model Screw Anchors in Soft Clays. |

Research Paper North western University US | : | Pull out Load Capacity of a Circular Earth Anchor Buried in Sand (WALLACE H. BAKER and ROBERTL.KONDNER) |

ASCE,No.SM2, pp.27-63 | : | Broms, B.B.(1964a),Lateral Resistance of Piles in Cohesive Soils, Journal of SMFED, Proc. |

ASCE,No.SM3, pp.123-156 | : | Broms, B.B.(1964b), Lateral Resistance of Piles in Cohesion less Soils, Journal of SMFED, Proc. |

Geo-Chicago2016GSP270 | : | Lateral Performance of Helical Piles as Foundations for Offshore Wind Farms: Sherif A.Y.Akl; Omar M. Elhami; and Mustafa A. Abu-keifa |

EJGE; Vol. 17 [2012],Bund. R | : | Performance of Helical Anchors in Sand;(Hamed Niroumand, Khairul Anuar Kassim, Amin Ghafooripour, RamliNazir1, H.S.Chuan) |

The Japanese Geotechnical | : | Soils and Foundations; Analysis and design methods of screw piles: Are view; Abbas Mohajeranin, Dusan Bosnjak, Damon |

Considering the scope of work for anchorage system,Geotechnical consultant identify the following scope

- To establish the Geotechnical Uplift Load carrying capacity of the Anchorage System.

- To Geotechnical Lateral Load carrying capacity of the Anchorage System. Following Geotechnical design procedure were adopted.

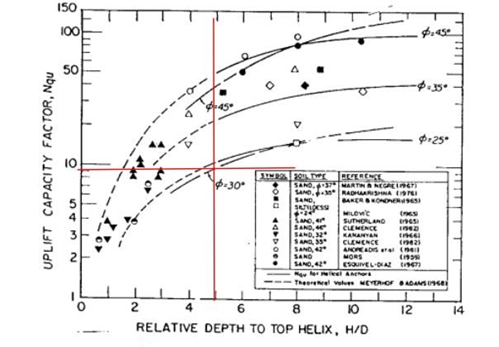

- Uplift Load Capacity Estimation Methodology

Determining uplift or Pullout load capacity for anchorage system is an in exact science & limited by an inexact environment, but carefully conducted testing can provide useful decision-making data. Further many variables involved can guide us to select an effective anchoring solution. Due to the array of unknowns both below and above the surface of any anchoring application–the soil medium,installation method, connections to the anchored structure – no one can guarantee a specific holding strength. There are three basic approaches to the design of shallow anchors(Flucker and Teng1965):

- Cone method

- Cylindrical shear method

- Semi empirical methods.

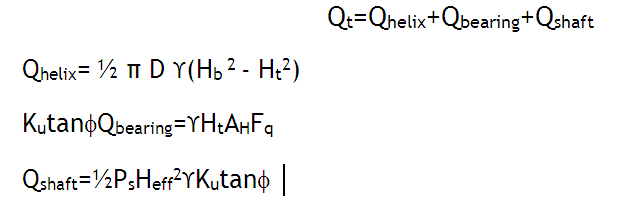

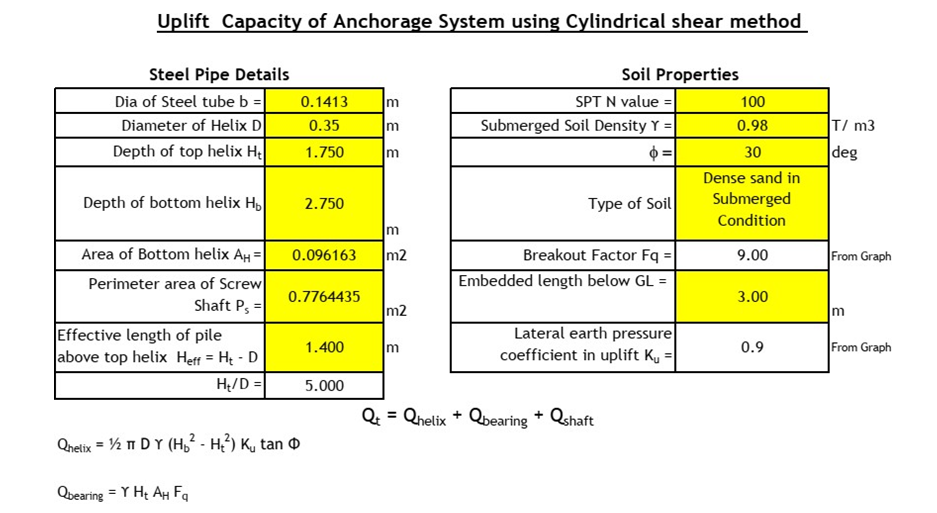

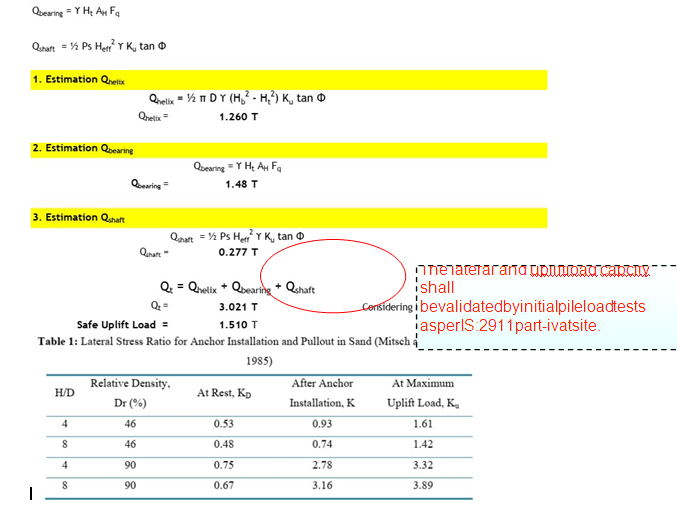

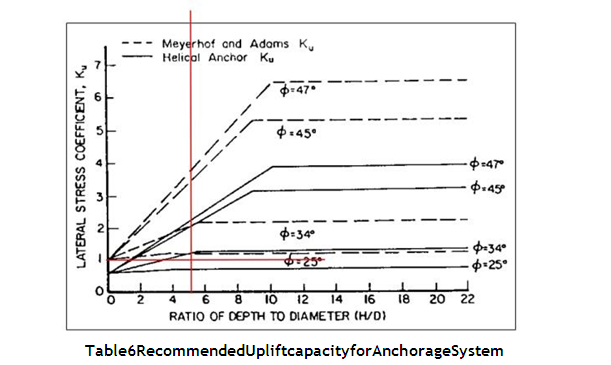

Up lift Load Capacity Estimation by Cylindrical shear method

The cylindrical shear method was introduced by Mitsch and Clemence(1985)for screw piles in sand and by Mooney et al. (1985) for screw piles in silt and clay; it allows for the estimation of the axial capacities of screw piles.

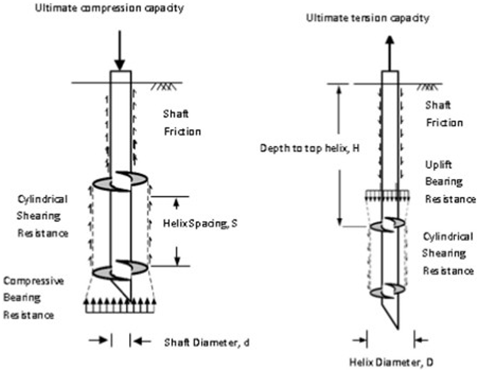

Figure2 Forces involved in cylindrical shear model under compression and tension(Nasr,2004)

It is supposed through the cylindrical shear method that a cylindrical shear failure surface is formed which connects the top and bottom helices, shown in above figureas having an axial capacity equal to the sum of the end bearing resistance below the bottom helix for compression and above it for tension, the sum of shear resistance along the cylindrical shear surface and the shaft friction above the top helix (e.g.Zhang et al., 1998; Livneh and Naggar, 2008; Tappenden et al., 2009; Sakr, 2009,2011;Hawkinsand Thorsten,2009).Equations related to the cylindrical shear method were consequent of the number of helices, the pile geometry, the soil conditions as well as the helical spacing(Nasr,2009).

The inter-helix spacing of bearing plates on the pile and the embedment ratio areseenaskeyparametersintheanalysisanddesignofthecompressivebearing capacity of screw piles in cohesion less soils. Zhang (1999) has recommended that screw piles under compressive or tensile loads with an embedment ratio greater than5 be classified as deep foundations, whereas those with an embedment ratio less than 5be classified ass hallow foundations.

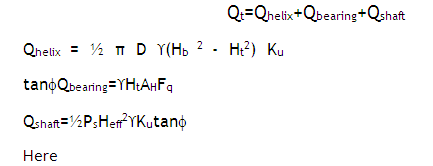

Multi-helix screw piles under deep conditions:

|

D=Diameterofhelix |

ϒ=SoilDensity |

|

Ht=Depthoftophelix |

Hb=Depthofbottom helix |

|

Heff = Effective length of pile above top helix i.e.(Ht– D) |

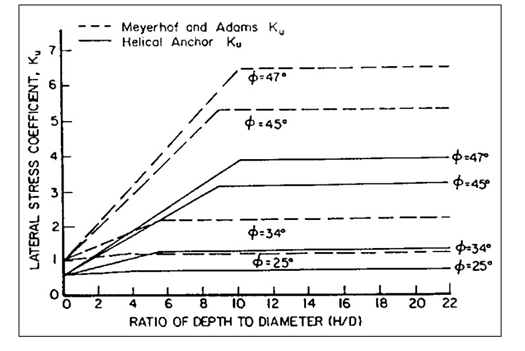

Ku=Lateralearthpressurecoefficientinuplift |

|

AH=Areaofbottomhelix |

Ps=Perimeterofscrew shaft |

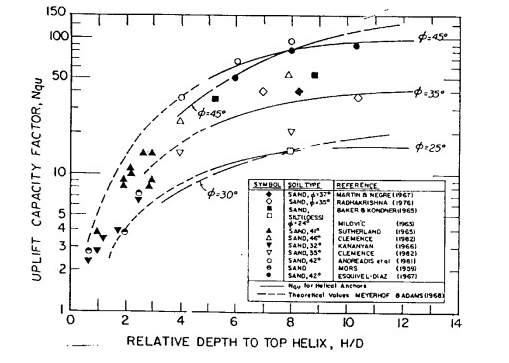

Figure3 Breakout Factor with Embedment DepthRatio(Mitschand Clemence,1985)

Figure 4 Recommended Lateral Stress Values (Ku) for Helical Anchors (Mitsch andClemence,1985)

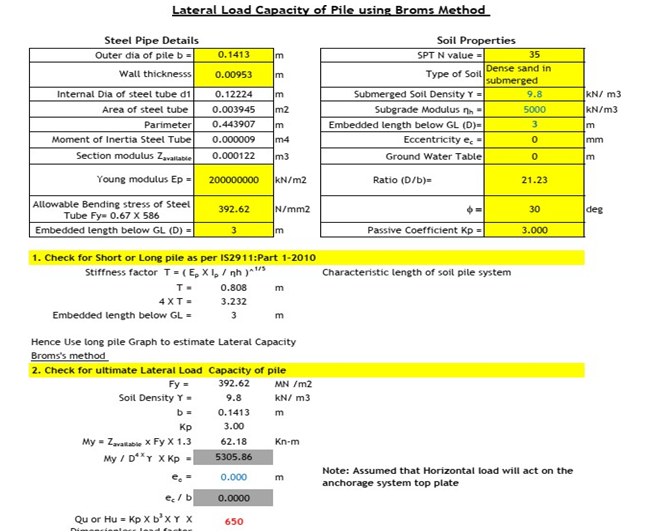

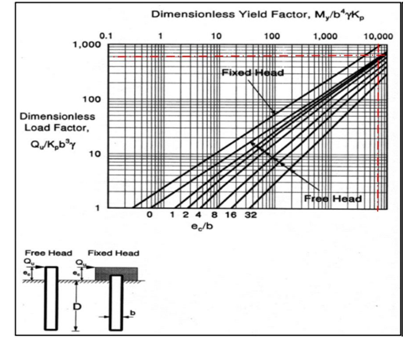

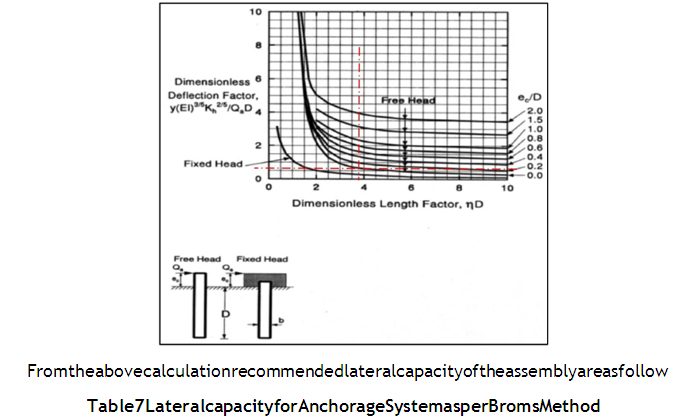

Calculation of Lateral Capacity

As a result of wind earthquake, waves, impact and lateral earth pressure most structures are subjected to lateral loads and moments in addition to the axial downward loads due to gravity. If these structures are supported on deep foundations, the foundations have to be designed for lateral loads so that they are safe against geo technical failure, structural failure,and excessive deflections.

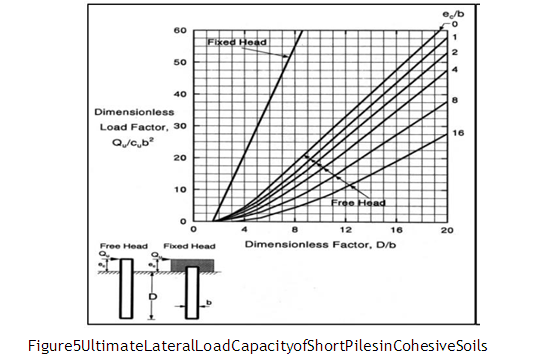

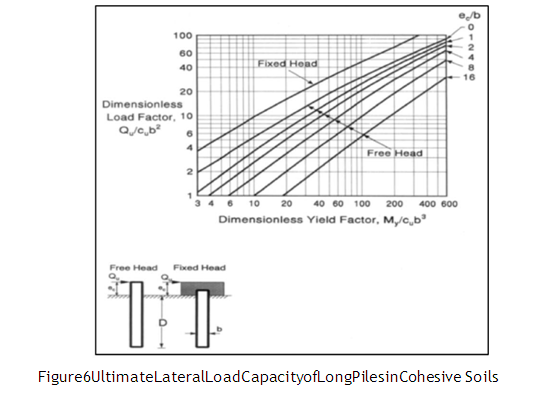

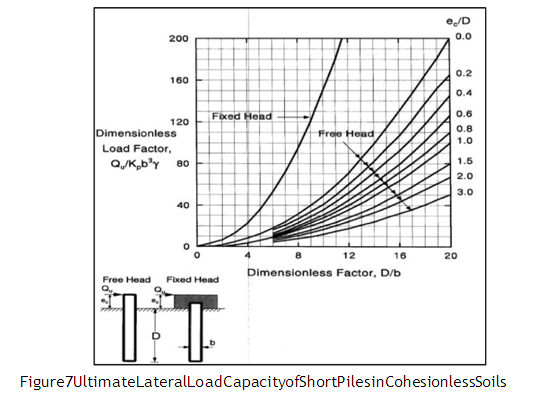

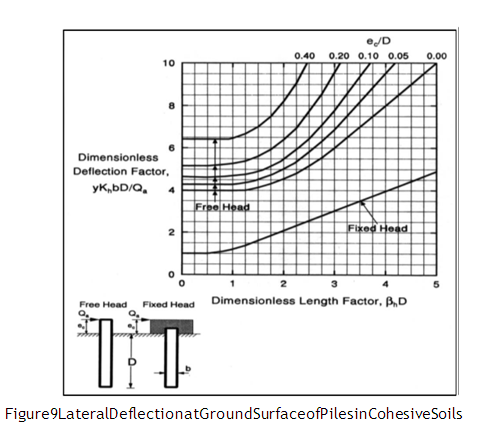

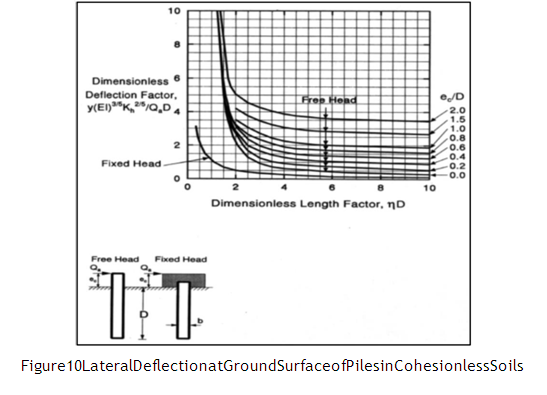

In engineering practice to withstand lateral load, laterally loaded piles are most commonly in use and in order to analyze them a number of theoretical methods are available such as the sub grade reaction approach by Barber (1953) and Matlock and Reese (1960), the ultimate lateral load approach by Broms (1964a). Among these aforementioned methods, Broms’ method is the simplest method to determine the lateral load and pile deflection at the ground surface using a convenient set of curves,ignoring axial load in the pile.

The lateral load-carrying capacity of a pile depends on the properties of the soil in which it is embedded. Now for this anchorage system horizontal load will be coming from the movement of solar panel. This horizontal load transfer to steel tube to helix part of the anchorage system & simultaneously to the surrounding soil. As horizontal load acting on the steel tube, there are two method to estimate the Lateral capacity of the system

- Horizontal Load Resisted by the Soil around the steel tube

- Horizontal Load Resisted by the steel tube

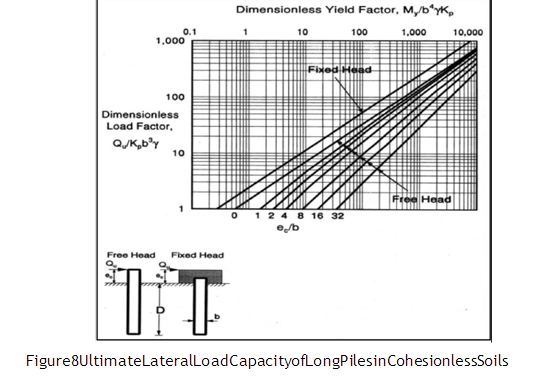

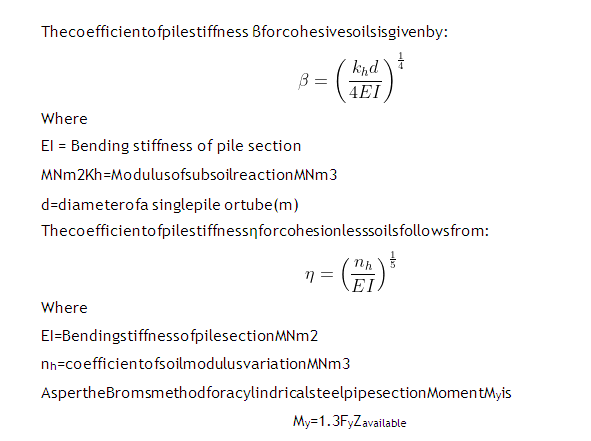

Broms’ method was presented in 964a, 1964b, 1965) for calculating lateral resistance of piles. A pile can be designed to sustain a lateral load based on Broms’ theory of earth pressure by referring to charts and graphs. According to the theory, piles can be divided into two groups; short rigid and long flexible. “Short” pile is one that is rigid enough to move in the direction the load is tending by rotation or translation whereas “long” pier is one that the top will rotate or translate without moving the bottom of the foundation, i.e. a plastic hinge will form. In other word, a pile is considered long when the relative stiffness of the pile with respect to the soil stiffness exceeds certain limits.

Broms’ developed lateral capacity methods for both short and long piles in cohesive and non-cohesive soil. Broms’ the orized that a short free headed pier rotates about a centre, above the lower end of the foundation, without substantial deformation along its axis. The resistance is the sum of the net of the earth pressures above and the passive earth pressure below the centre of rotation. The end bearing influence or effect is neglected. Like wise, the passive earth pressure on the uppermost1.5 diameters of shaft and the active earth pressure on the back of the pile are neglected. The basic parameters for soil layer system, i.e. depth of each layer, type of soil, fineness of cohesionless soil, Field SPT value (N), location of GWT from GL,head condition of pile, pile material, unit weight of soil (γ), embedded pile length(D),design parameter(deflection/load),working load or allowabled eflection,eccentricity (ec) etc. and basic parameters for pile i.e. diameter of pile (b), bar dia,bar no., clear cover, yield stress of steel (fy), compressive strength of concrete (f’c)etc.

Design Parameters

Following design parameters was used to estimate the Lateral & Uplif the lical pile capacity

- 5mm anticipated deflection was considered to estimate lateral pile capacity.

- From the field data N value is more than 100 & hence for design purposeΦ=30 degconsidered

- 980 to 2.040gm /cc &hence for design purpose 1.980gm/cc considered.

- Sub merged density of the soil=0.980gm/cc

- Diameter of the anchorage shaft/tube=141.3mm

- Length of the anchorage system=3.00m

- Helixdia=0.35m

Geotechnical Calculations Uplift Capacity as per Cylindrical shear method

Refer Section 3.1. following are the design parameter to estimate uplift load carrying capacity of the anchorage system;

|

ShaftDiain mm |

Dia ofAnchorage System |

Founding Depth ofbelowbedlevelin m |

DesignMethodology |

UpliftCapacity(T) |

|

141.3 |

350mm |

3.00 |

Cylindrical ShearMethod |

1.510 |

Lateral Capacity for Anchorage System(Broom Method)

One of the most common and simplified method is proposed by Broms (1965) that determines the lateral load capacity and pile deflection at ground surface. Broms usess ever algraphical charts to obtain ultimate bearing capacity and lateral deflection. A pile can be designed to sustain a lateral load based on Broms’ theory of earth pressure by referring to charts and graphs.According to the theory, piles can be divided into two groups;short rigid and long flexible.

Following are the assumption to estimate lateral load carrying capacity of the anchorage assembly.

- SPT assume din the capacity estimation is 100

- Angle of Internal friction for soilf=30(where assumed SPT more than 100 blows)

- Anticipated deflection=12.5mm

- Allowable bending stress of steel Fy=0.67X586=392.62N/mm2

- Sub merged Soil Density=9.80kN/m3

Lateral Capacity for Anchorage System

AsperICC-IBC-2009clause1810-3.3.2Allowable lateral load. Where required by the design, the lateral load capacity of a single deep foundation element or a group there of shall be determined by an approved method of analysis or by lateral load tests to at least twice the proposed design working load. The resulting allowable load shall not be more than one-half of the load that produces a gross lateral movement of 1 inch (25 mm) at the lower of the top of foundation element and the ground surface, unless it can be shown that the predicted lateral movement shall cause neither harmful distortion of, nor instability in, the structure, nor cause any element to be loaded beyond its capacity.”

Considering 12.5 mm lateral deflection which is less than 25 mm as proposed byICC-IBC-2009

|

ShaftDiainmm |

Diaof AnchorageSystem |

Founding Depth of belowbedlevelinm |

DesignMethodology |

LateralCapacity(T) |

|

141.3 |

350mm |

3.00 |

BromsMethod |

2.00 |

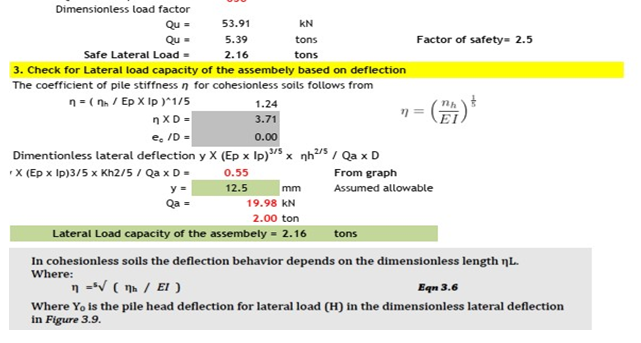

Conclusion & Recommendation for Anchorage System

From the above calculations & results; following are the recommendation for Uplift Capacity & Lateral Capacity, based on the 350 mm anchorage diameter & 3 m length ass how nin the Typical details of anchorage system for Floating Solar Panels

Table 8 Recommended Geotechnical capacity for Anchorage System

|

ShaftDiain mm |

TypeofCapacity |

FoundingDepthbed level inm |

FoundationStrata |

GeotechnicalCapacity(T) |

|

141.3 |

UpliftCapacity |

3.00 |

CompletelyWeatheredRock |

1.510 |

|

LateralCapacityby BromsMethod |

3.00 |

CompletelyWeatheredRock |

2.00 |

It is a general observation that in actual pull out & lateral load test will be on higher site.

Note: The only method of accurately predicting the load capacity of an anchoragesystem at a specific site is by an onsite proof test (Lateral & Uplift) of the anchor under local conditions, installed and loaded in the same manner as the intended application before adopting above design capacity.

Annexure-I(Report Limitations)

This report has been prepared for M/s Tethys Business and Projects (P) Ltd. This geotechnical assessment report is based on the data provided and from judgement ofundersigned based on his experience. Scope of this assessment report is limited to defining Geotechnical Lateral &Uplift capacity of the anchorage system.

Professional judgments and recommendations are presented in this assessment report. They are based partly on evaluation of the technical information gathered,partly on historical reports and partly on our general experience with sub-surface condition in the area. We do not guarantee the performance of the project in any respect other than that our engineering work and the judgments rendered meet the standards and care of our profession. It should be noted that the estimation of geotechnical Lateral & uplift capacity is based on the various discussion held with theofficer & agreed methodology. Undersigned is not responsible for the construction methodology, quality control at site & the structural stability of the anchorage system. If during construction design loads and/or configuration change,we should be notified immediately in order that we may evaluate effects, if any, on anchorage system performance.The geo technical assessment presented in this report are applicable only to this specific site. This data should not be used for other purposes.

Due to the Limited scope of the Geotechnical consultant (means only estimation of Lateral & Uplift capacity of the anchorage system) & Limited technical in formation about the project shared with the Geotechnical Consultant, before adopting the design parameters for design Purpose Please note that the following points

- Anchorage system(Steel tube&helix) structural design was not in the scope of Geotechnical Consultant. Geotechnical Engineer is not responsible for the quality control at site, installation of anchorage system & behaviour of the anchorage system during design life.

- Due to the array of unknowns both below and above the surface of any anchoring application – the soil medium, installation method, local climate,connections to the anchored structure– no one can guarantee a specific holding strength.Load capacity is not a simple function of“soil class”but also of real time moisture content,compaction,root penetration,installation method,pull-out load angle,and other factors unique to the installation’s time and place.

Gallery

Copyright © 2025 Tethys Business & Projects P Ltd | Powered by Conceptly WordPress Theme